The concept of in-orbit 3D printing has taken a revolutionary leap forward with recent experiments aboard the International Space Station (ISS). Scientists and engineers are now exploring the possibility of satellite self-replication, a groundbreaking advancement that could redefine space exploration and manufacturing. This technology promises to transform how we approach satellite deployment, repair, and even deep-space missions.

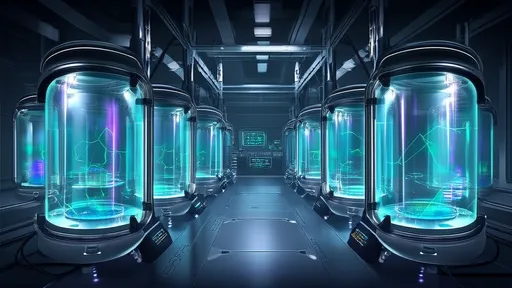

At the heart of this innovation is the idea that satellites could one day manufacture copies of themselves in space. The ISS has become a testing ground for this futuristic vision, with astronauts and researchers working tirelessly to refine the processes involved. Using advanced 3D printing techniques, components can be fabricated in microgravity, paving the way for autonomous satellite replication.

The Challenges of Space-Based Manufacturing

Creating functional satellites in the harsh environment of space is no small feat. Traditional manufacturing methods rely on Earth's gravity and stable conditions, neither of which are available in orbit. Engineers have had to develop entirely new approaches to 3D printing that account for microgravity, extreme temperatures, and limited resources. The materials used must withstand cosmic radiation and the vacuum of space while maintaining structural integrity.

Another significant hurdle is power consumption. 3D printers require substantial energy to operate, and in space, every watt counts. Researchers are experimenting with solar-powered systems and energy-efficient printing methods to make the process sustainable. The ISS provides an ideal platform for these tests, offering both the microgravity environment and the necessary infrastructure to support such experiments.

Breakthroughs in Microgravity 3D Printing

Recent successes aboard the ISS have demonstrated that 3D printing in microgravity is not only possible but also highly effective. Astronauts have printed tools, spare parts, and even small satellite components with remarkable precision. These achievements are critical stepping stones toward the ultimate goal of self-replicating satellites. The ability to manufacture parts on-demand reduces the need for costly and risky resupply missions from Earth.

One of the most exciting developments is the use of recycled materials. Scientists are exploring ways to repurpose space debris and old satellite parts into raw materials for 3D printing. This approach not only addresses the issue of space junk but also creates a sustainable loop of resource utilization. Imagine a future where defunct satellites are broken down and rebuilt into new, functional ones—all without human intervention.

The Future of Autonomous Satellites

The implications of satellite self-replication are profound. Autonomous satellites capable of repairing or replicating themselves could extend mission lifespans indefinitely. Deep-space probes could launch with the blueprints for replacement parts, ensuring they remain operational for decades. Colonies on Mars or the Moon could leverage this technology to build infrastructure without relying on shipments from Earth.

However, this future is not without its ethical and logistical challenges. The idea of self-replicating machines raises questions about control and safety. How do we prevent unintended replication or malfunctions? International regulations will need to evolve to address these concerns, ensuring that space remains a safe and collaborative environment.

Collaboration and Next Steps

The journey toward fully autonomous satellite replication is a collaborative effort. Space agencies, private companies, and academic institutions worldwide are pooling their expertise to overcome technical barriers. The ISS serves as a unifying platform where these diverse teams can test and refine their ideas. Upcoming missions will focus on scaling the technology, moving from small components to entire satellites.

Public interest in these developments is growing, and for good reason. The ability to manufacture and replicate satellites in orbit could drastically reduce the cost of space exploration. It opens doors to missions that were previously deemed too expensive or impractical. As we stand on the brink of this new era, one thing is clear: the future of space technology is being written aboard the ISS, one 3D-printed layer at a time.

By /Jul 10, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 9, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 10, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 9, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 9, 2025